Honeywell Joins PIT’s xBridge in Leading the Way to Cleaner Airport Air

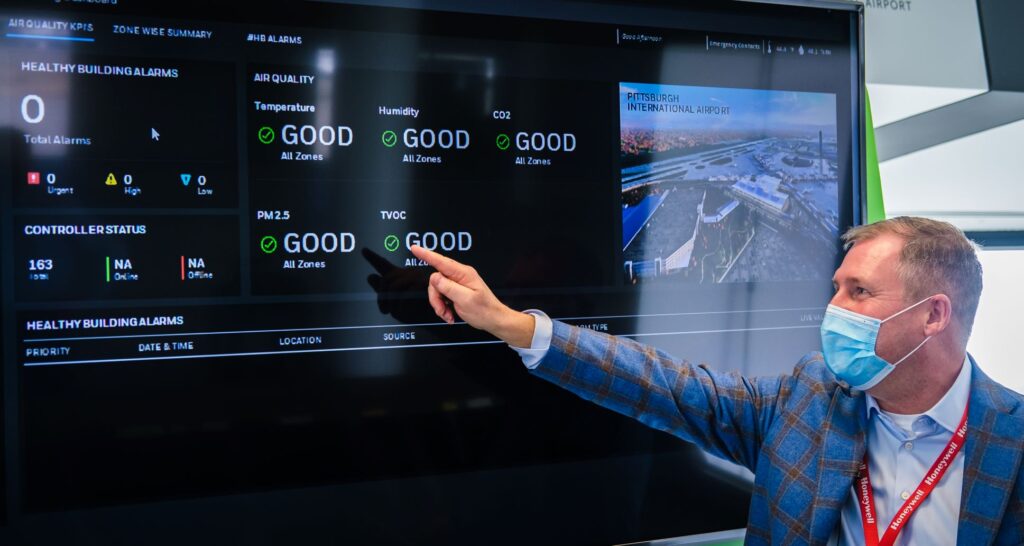

Ensuring clean air in airports has never been more important – that’s why Pittsburgh International Airport has partnered with Fortune 100 company Honeywell to develop a live dashboard measuring air quality that will help airport staff identify and correct issues in real time.

The dashboard is being tested and developed as part of the airport’s xBridge, a 10,000 square-foot innovation center inside the airport that launched last year. Based on the success of xBridge pilot systems, PIT may expand the technology throughout the airport.

Senior Vice President of Public Safety, Operations, and Maintenance at PIT, April Gasparri, said:Working with companies like Honeywell through our xBridge innovation center allow us to not only test new technologies but also look for ways to solve bigger challenges that will improve the experience for our airline partners, staff and passengers.

The emphasis on air quality has greatly increased due to COVID-19, and we are looking to adjust our facilities for the long term to create safer environments for travelers and staff.

The Honeywell Healthy Buildings dashboard at xBridge measures key indoor air quality parameters such as temperature, humidity, carbon dioxide, particulate matter and volatile organic compounds.

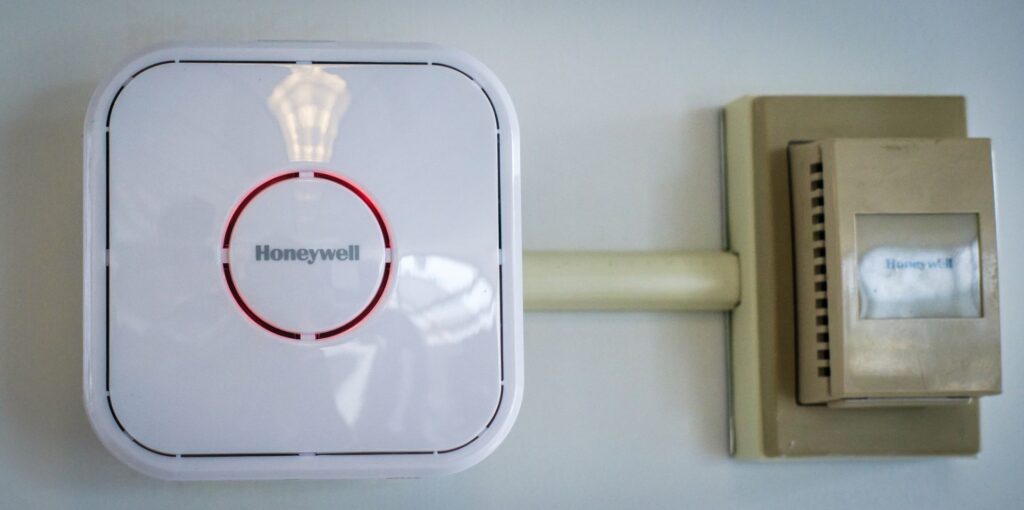

A network of sensors connected to the dashboard, which is integrated into existing systems within the airport, provide real-time updates on air quality to help facilities staff quickly identify and correct critical building issues to help reduce the spread of airborne disease.

For example, if the amount of carbon dioxide rises above acceptable levels in a certain area, that would likely indicate the space is overcrowded. Airport staff could adjust ventilation or respond with staff to encourage social distancing or help clear out an area.

Vice president and general manager of services, for Honeywell Building Technologies, Keith Fisher, said:The team at Pittsburgh International Airport has an innovative mindset and is looking to identify ways to further improve its indoor air quality to solve these problems as well as potential airborne virus transmission. We’ve been able to deploy new solutions at PIT to keep it current with the latest technology and create a safer and healthier space without any downtime.

Additionally, the airport is planning to use condition-based maintenance focused on filters in its air handling units through Honeywell Forge Digitized Maintenance. When using this system, the airport will be able to immediately change filters that are becoming less effective and to manage costs by avoiding unnecessary changes.

The partnership with Honeywell is the first to be announced as part of the airport’s xBridge innovation center. Several other partnerships with private companies looking to develop and test new technology at the airport are expected to be announced in the coming months.

Senior Vice President of Information Technology at Allegheny County Airport Authority, Katherine Karolick, said:The xBridge is a physical manifestation of the innovative mentality we’ve been cultivating here at PIT for years. This will be a proving ground for new technology that will benefit the airport, our airline partners and the passengers we collectively serve.

You need to create an environment and ecosystem to make (innovation) happen. This space has everything we need to tap into the collective brainpower of our industry and region, design innovative solutions, and accelerate the development of those solutions.

Commonly found in the tech sector, innovation centers bring various aspects of the product development process together into one space devoted to maximizing brainpower and resources, and testing new ideas in real time. For example, the xBridge will contain maker space, an open design studio, and mockups of the various parts of an airport, such as concessions and the arrivals area.

PIT has been at the cutting edge of the industry with several recent initiatives, including Neighborhood 91, the first development in the world dedicated to industrializing the additive manufacturing industry; a first-of-its-kind microgrid that will power the entire airport via onsite natural gas wells and solar panels; and automated floor scrubbersv augmented with UV lights to set the standard for maintaining clean and healthy terminals.

This article was originally published by Allegheny County Airport Authority.