Propex offers a full line of woven and nonwoven geotextiles to help build and rebuild key infrastructure including roads, bridges, railways, and airports.

Denver International Airport | Case Study

Denver International Airport needed an American made product to repair heavily used runways. GEOTEX® nonwoven geotextile was used to separate the cement treated subgrade (CTS) from the new pavement.

The Denver International Airport (DIA) is the sixth-busiest airport in the United States so some detrition on their runways is to be expected. DIA needed to replace sections of one of its most heavily used runways, 17L/35R, as well as the connecting taxiways as it was showing signs of distressed pavement panels.

Propex GEOTEX® 701 was chosen to be used as a bond breaker between the cement treated subgrade and the new pavement. GEOTEX 701 is a polypropylene, staple fiber, needle-punched nonwoven geotextile that provides separation between dissimilar materials and meets FAA specifications. This was the first project DIA completed using federal stimulus money.

GEOTEX is made in the U.S., which made it easy for the contractor to comply with the Buy America clause in the stimulus package.

The runway was closed for 90 days allowing for 130,000 square yards of GEOTEX 701 to be installed. The result yielded a runway rehabilitation strong enough to accommodate the newest generation of jumbo jets.

Features & Benefits

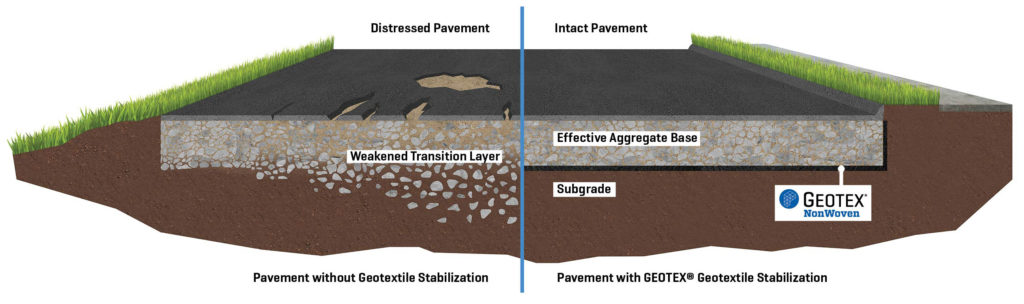

- Breaks bond between cement treated subgrade (CTS) and concrete pavement, reducing stress in concrete and improving performance

- Separates aggregate from soil, extending road life and reducing maintenance costs

- Easy to install, saving on time and labor costs

- AASHTO/NTPEP Certified

- Resists biological and chemical environments normally found in soils

- Available in a variety of styles to fit specific project needs

Visit our website for more information, product samples or other inquiries or call customer service at 1.800.621.1273