Mechanical Belt Conveyor Solutions for Airports

Flexco Understands Airports

Travelling by aeroplane is becoming more convenient so more passengers are choosing it to travel. In short, this increase means that airport conveyor systems will be facing an increasing amount of stress. Flexco knows your struggles, which is why we provide solutions that tackle basic jams and rips to complete belt conveyor failure.

Our main goal is to understand your needs and provide real solutions. By carrying out site visits and walkthroughs, conducting research, and leading conversations, we are able to achieve this goal. In total, this allows us to become your partner in productivity.

The Flexco name is synonymous with mechanical belt fastening systems. By combining durability and ease-of-use, they have become the standard for many across the airport industry. No matter which MBF you use, we can all but guarantee your airport’s baggage belt will keep moving.

However, mechanical belt fasteners aren’t the only option; some prefer to use endless splicing equipment. To address this, we offer the Novitool® Aero® Splice Press. In 10 minutes or less, your workers can perform a full endless belt splice.

A unique option that we offer to our customers is our training and educational opportunities. Through virtual, in-class, and on-site offerings, we can give workers the tools they need to increase the bottom line.

Overall, our product offerings help you take down even the most common logistical baggage handling system problems. No matter what you are trying to accomplish at your facility, we have your needs in mind. From utilizing our belt maintenance tools for full belt repair to addressing the most specific transfer points with our Segmented Transfer Plates, Flexco has you covered.

Looking to add Flexco belt conveyor solutions to your airport’s belt loader or your entire baggage handling system? Be sure to view our solutions or contact Flexco.

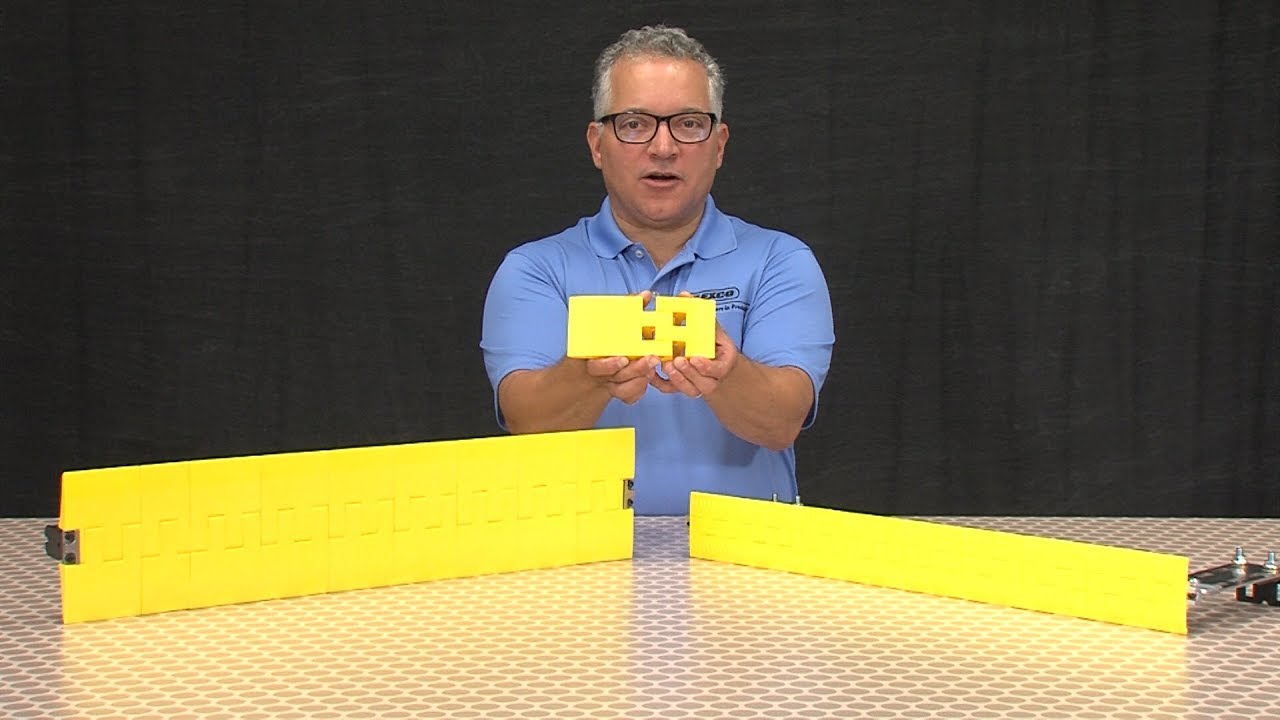

Segmented Transfer Plates

Flexco Segmented Transfer Plates are the key solution for reducing luggage damage and jams at conveyor transfers. The segmented design allows the transfer plate to be installed and operate while touching the belt, creating a tight seal that reduces the chance of luggage straps, wheels, and tags from becoming lodged in the transfer.

Mechanical Belt Fastening Systems

Alligator® Staple, Clipper® Wire Hooks, and Clipper® G-SeriesTM all offer fast installation that is useful when having to splice conveyor belting during a critical breakdown. Offered in high wearing metals high tensile and stainless steel, these mechanical fasteners are up for the challenges faced in baggage handling systems running at higher speeds and conveying a larger quantity of bags.

Novitool® Aero® Splice Press

The Novitool® Aero® Splice Press is the best and fastest endless splicing press available on the market, capable of completing a splice from preheat to cooldown in as few as 10 minutes. With a unique platen design creating a flat splice and consistent heating profile, the splice easily flows under diverters reducing the opportunity for catastrophic splice failure, which keeps belts running longer.

Novitool® Pun MTM Mobile Finger Punch

The Novitool® Pun MTM Mobile Finger Punch can be used at the conveyor site and does not require electrical power, accelerating splice preparation to save downtime. Its precision finger cutting boards ensure fingers are cut perfectly each time. No hammers or punches are required, adding an extra element of safety.

Smart Clamps

Flexco Smart Clamps are the safest and fastest method for securing conveyor belts while installing belt splices on the conveyor. A simple tap of the wedge strike plate instantly locks the clamp to the belt. There are no bolts to tighten, check, and then loosen after use. With Smart Clamps, when you are finished securing the belt, a simple tap on the pull loop disengages the wedge allowing for quick removal of the clamp.

Clipper® 845LD Belt Cutter

The Clipper® 845LD Belt Cutter provides a fast and accurate cut in a single pass, utilizing a fully enclosed blade during cutting operations for a safe cut. A straight cut helps ensure the belt will track straight. Its bi-directional blade design and dual-drive shafts allow the operator to cut the belt while working from either end of the belt cutter.

Laser Belt Square

The Flexco Laser Belt Square can be used to quickly produce an accurate line for marking and cutting. Splicing a belt that is not properly squared can lead to belt tracking issues and an increase in unscheduled conveyor downtime.