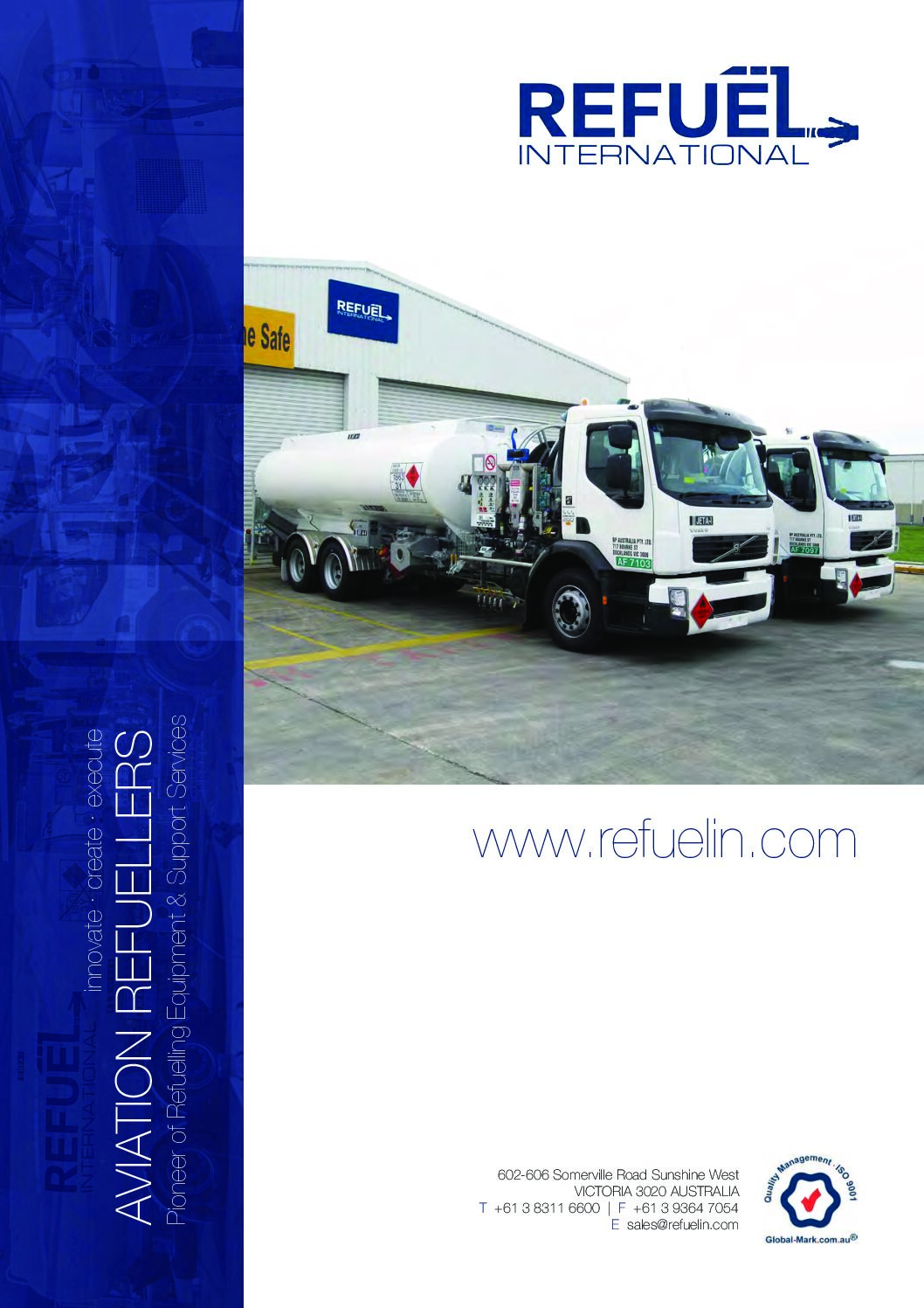

Aviation Refuellers

Any Chassis, Any Capacity

Refuel International Aviation Refuellers (bowsers) are designed for efficient and safe aircraft refuelling at any location; transferring fuel into an aircraft from its vehicle mounted storage tank via a pump, filter and metering system. Their proven designs incorporate innovation coupled with components which are compliant with the international aviation industry standards. All of their refuellers are designed to achieve fast and efficient flow rates.

When designing the refuelling module structure; they work towards minimising the overall size while maximising the amount of components that fit within. This facilitates ease of pre-fabrication and also ease of transferring the refuelling module to another truck if required.

Internationally this makes their product offering more appealing as their modules are easily integrated onto any make of chassis by their International integration partners all over the world.

Their refuellers (bowsers) are integrated with a rigid chassis or prime mover and trailer combinations. Product tanks have capacities ranging from 2600L to 23,000L (on a rigid chassis) or articulated refuellers which have tank capacities of 23,000L and larger. Designed specifically for aviation fuels, all units are built to the customer’s specification and are equipped with everything needed, to customer specific requirements.

Efficient Flow Rate:

Fuelling is possible through overwing hosereels, underwing hosereels and EWP’s, at variable flow rates of up to 2,200lpm for underwing refuelling and 200 lpm for overwing refuelling. Bottom loading can achieve a rate of up to 1,500 lpm & is linked to primary and secondary failsafe overfill protection systems.

Safety Features:

- Fuelling components interlocked to the Vehicle Immobilisation System

- Electric Deadman handles

- Emergency Interlock / Brake Override

- Emergency Stop / Fuel Shutdown buttons

- Emergency Engine Stops