Airport Technology

Systems and Solutions for Perfect Docking with All Aircraft Types.

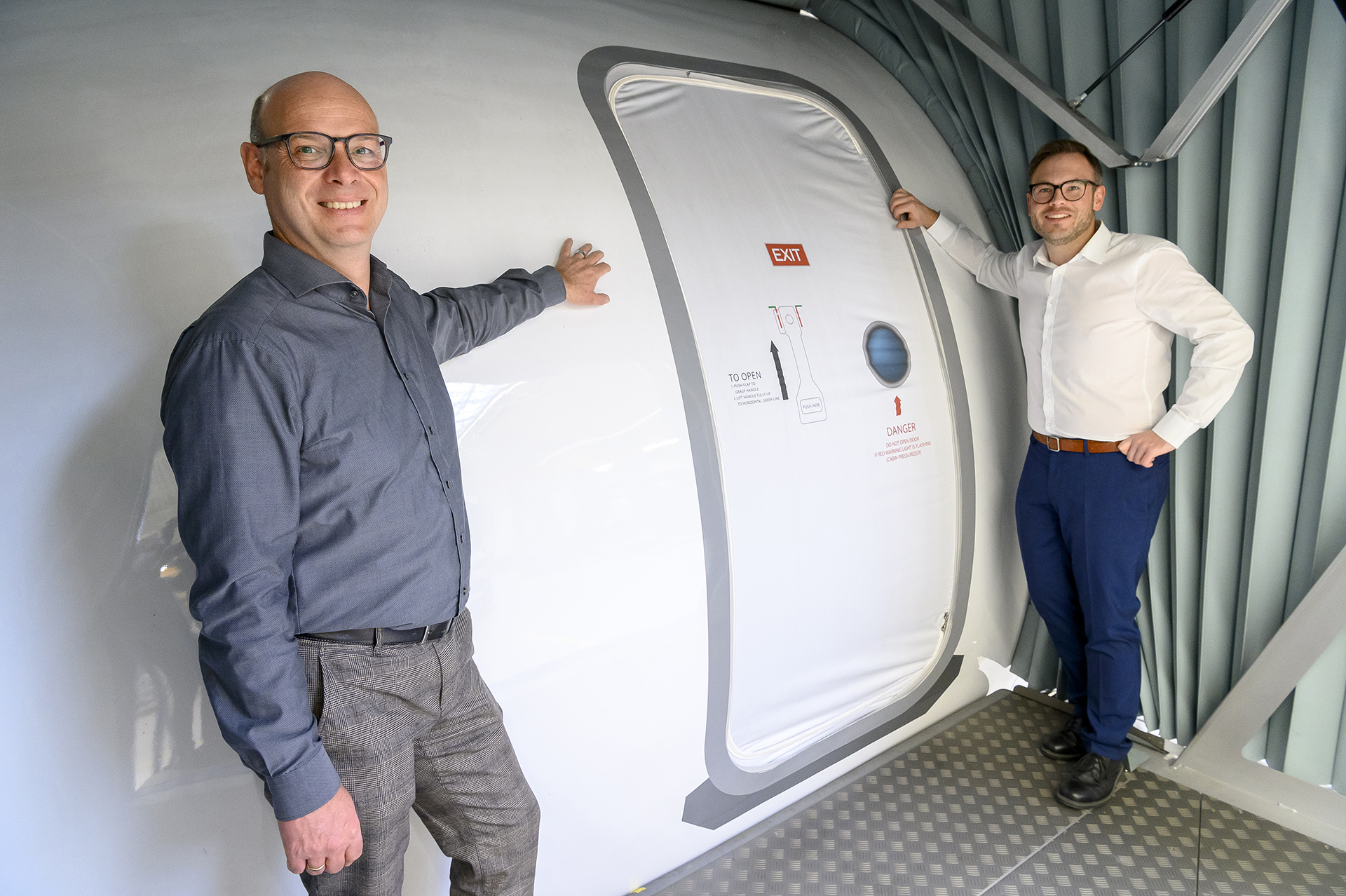

Whether it’s a flight for holidays or for business, when you board your plane at numerous airports around the world, you will be walking through a folding canopy manufactured by HÜBNER.

Our folding canopies fit perfectly with a wide variety of aircraft body contours and offer passengers optimal weather protection. The patented pivot mechanism allows precise docking of the passenger boarding bridge on the aircraft fuselage, and adjustable bumpers guarantee a perfect seal between the folding canopy and the body of the plane.

Thanks to our unique modular system, we can make our folding canopies meet the individual requirements of our customers fully and exactly. There are also numerous design options. For example, we offer translucent or colored canopy models. All of the materials we use – regardless which model is selected – are heat, cold and UV-resistant and meet all international fire safety standards.

Folding Canopies for Passenger Boarding Bridges

For Optimal Weather Protection during Boarding.

We produce folding canopies for passenger boarding bridges and wharf-ship connections that provide passengers with optimal weather protection. Just like our famous folding bellows for the transport industry, the folding canopies are manufactured using our own coated fabrics. They also meet the requirements of NFPA 415.

Our folding canopies can be equipped with four different drive systems: a manual drive, a 24v DC drive (for mobile aircraft boarding stairs), a 110v drive and a 230v drive. The canopy drive operates via a central motor that is designed to stand up to the extreme weather conditions encountered at harbors and airports. It is equipped with a freewheel safety mechanism and is protected against overheating. The use of the latest drive motors also allows a reduction of the opening and closing time of the folding canopy by approximately 45% – a clear benefit in optimizing passenger handling processes.

Folding Bellows, Corrugated Bellows and Fairings

Flexible Connecting Elements for All Applications.

We produced our first folding bellows in 1952. At that time, together with the Henschel Company in Kassel, we brought their first articulated bus to the market. In 1956, the first folding bellows for rail vehicles came on the market when we equipped the TEE high-speed train with folding bellows, and in 1971 we delivered our first folding bellows for airport technology. Over the years, we have been continually developing our folding bellows so that today they are put to use in all kinds of different applications– for example as flexible connecting elements between skyscraper towers or as noise protection equipment during drilling operations. And we have also extended and enhanced the look of our folding bellows. Nowadays, translucent or multicolored folding bellows can be seen in use in many places.

On-Site Service

Ready to Be of Service around the World.

We always are open to hearing from our customers – also after our products have been delivered. Our service support includes everything that is necessary for the optimal use of our products and solutions – from product training to spare parts to repair services to refurbishment options.

Whatever you may require: Simply get in touch with us – our international Service Team will be delighted to assist you.