Robson Handling Technology

Robson Handling Technology undertake turnkey Airport Baggage Handling Systems, EDS Installation & Integration projects on a worldwide basis.

Integrating the latest technology within our systems from initial enquiry to handover to deliver:

- Dynamic speed control for increased throughput

- De-risked installation & commissioning activities – 3D laser scanning / 3D layout design / 3D clash detection with virtual reality integration / Simulation & emulation for easier commissioning & integration / Plug & play controls, distributed controls architecture

- Minimal disruption to on-going Airport operations – Detailed phasing plans allowing operations to continue

- Minimal HBS footprint – More space for retail

- Safer, more reliable system – IATA 753 compliant / AI – Human Intruder Detection

- EDS Integration – 30+ Years Experience in EDS Integration / 200 plus EDS Machines Integrated including STD 1, 2 & 3

Robson have over 400 projects worldwide, with systems working in Heathrow, Gatwick, Manchester, Stansted, Hong Kong, New York, Montreal and more.

From single check-in desks and self bag drop solutions, to a fully automated Baggage Handling System, Robson have highly skilled design, manufacturing and installation engineers to deliver effective Airport Baggage Handling Solutions to meet the needs of airports of any size or configuration.

Seamless integration and system upgrades are a reality with Robson Modular Airport Baggage Handling Systems. Bespoke designs that maximise re‐use of existing conveyors and are adapted to local constraints and level fluctuations offer ‘best value’ solutions to all our clients.

Tagomat® – Remote Self Tagging

Improve social distancing space in airports by giving passengers the ability to print bag-tags anywhere Tagomat®, Touchless, Simplistic and Efficient Self Service bag tagging solution…. Minimise contact by utilising our Tagomat® units,

The battery powered/wireless tagging station Tagomat® can be used in train stations, rental car buildings, hotels, convention centres, parking lot and in airports to reduce congestion at today’s hardwired clustered kiosks.

Closely aligned with todays travel patterns the Tagomat simplifies self-tagging by providing the airport with a mobile and quick bag tag solution. Passengers quickly scan their electronic boarding pass get their bag tags in 10 seconds – providing a more seamless start to their journey.

Tagomat® enhances the passenger experience by providing the “ready to go” feeling. Airports benefit from passengers spending less time in non-commercial areas of the airport. Voted as a solution that can improve today’s airport experience.

- Quick – bag tag available in 10 seconds

- Intuitive and easy to use

- Mobile – small in size and wireless

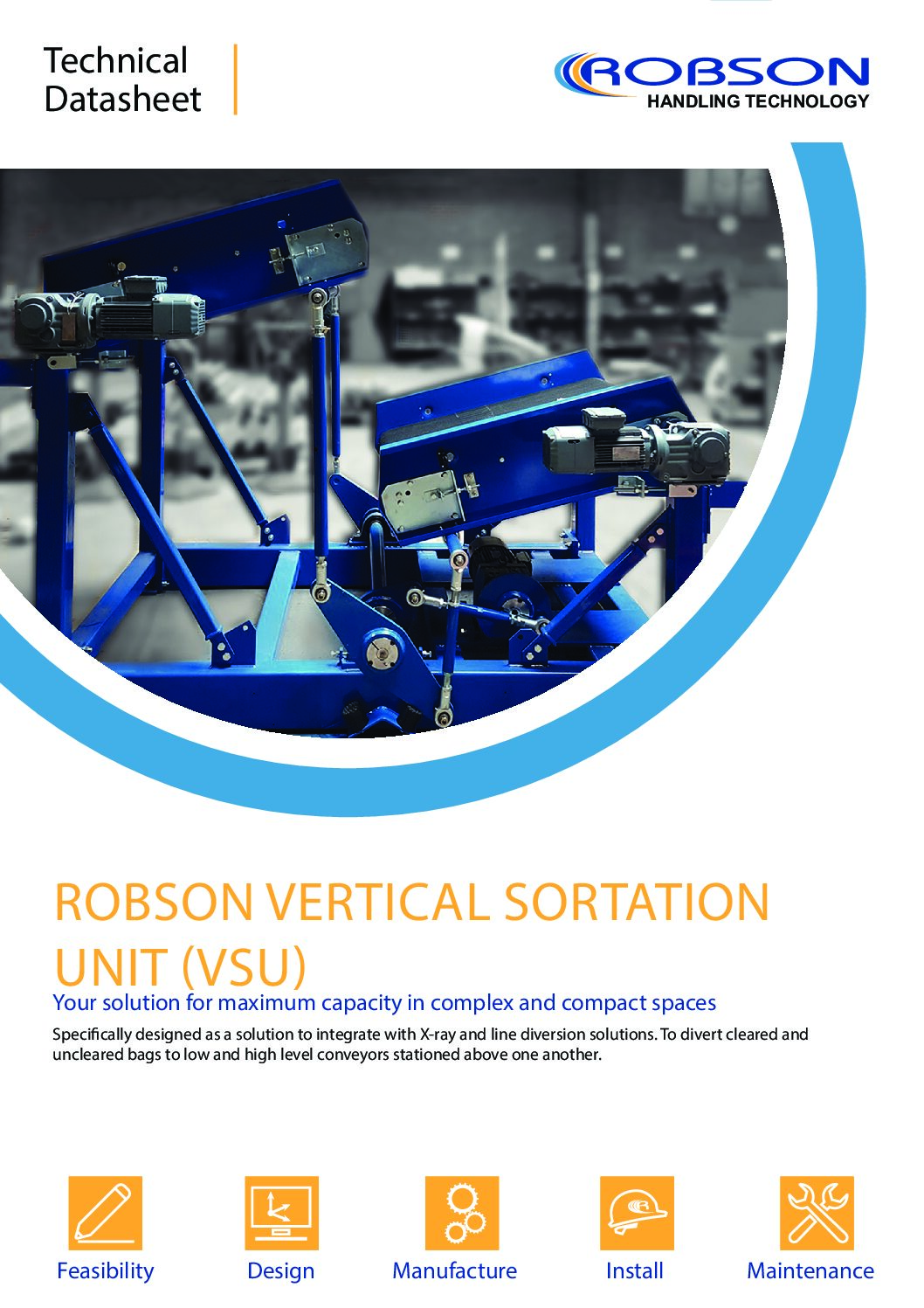

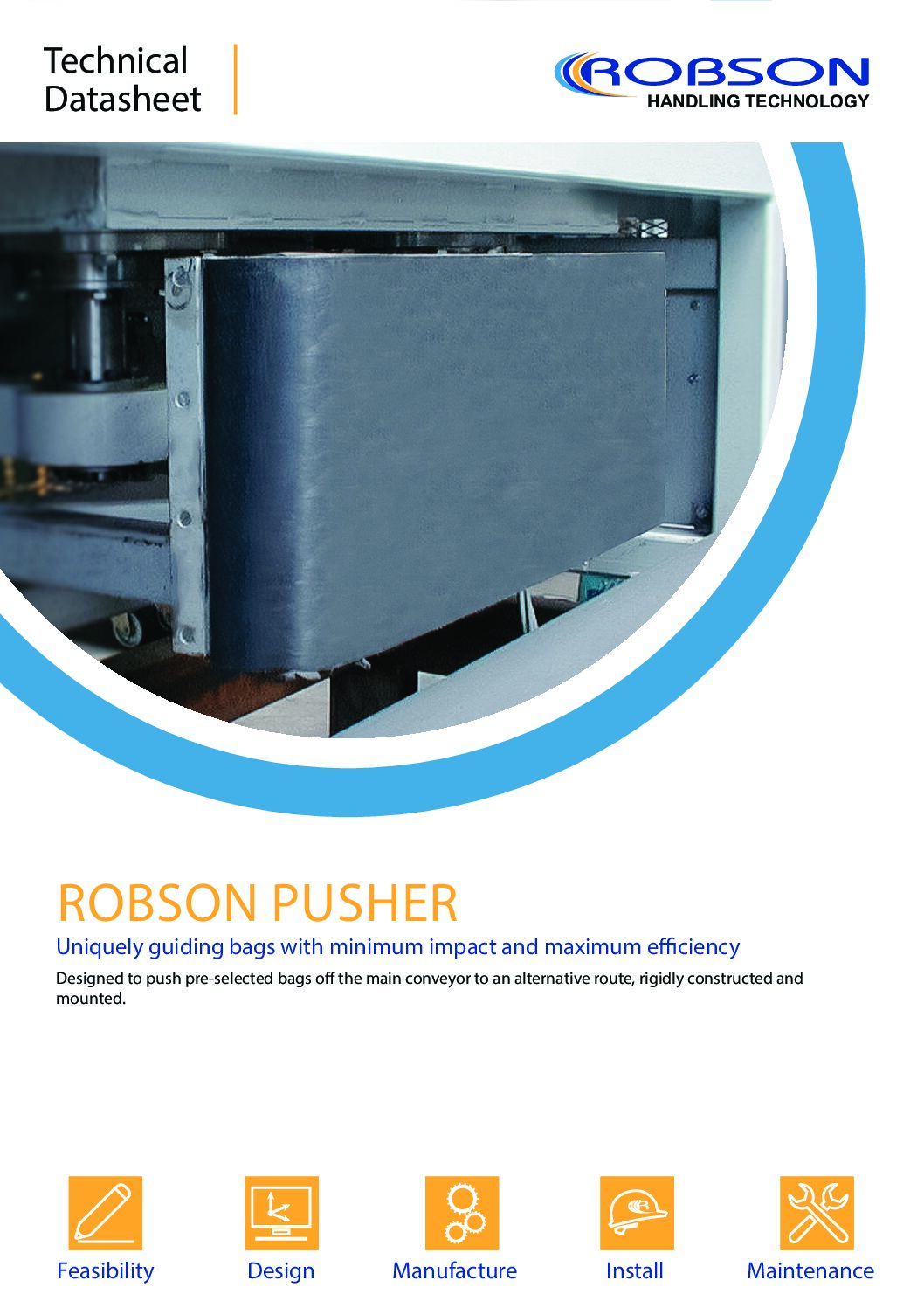

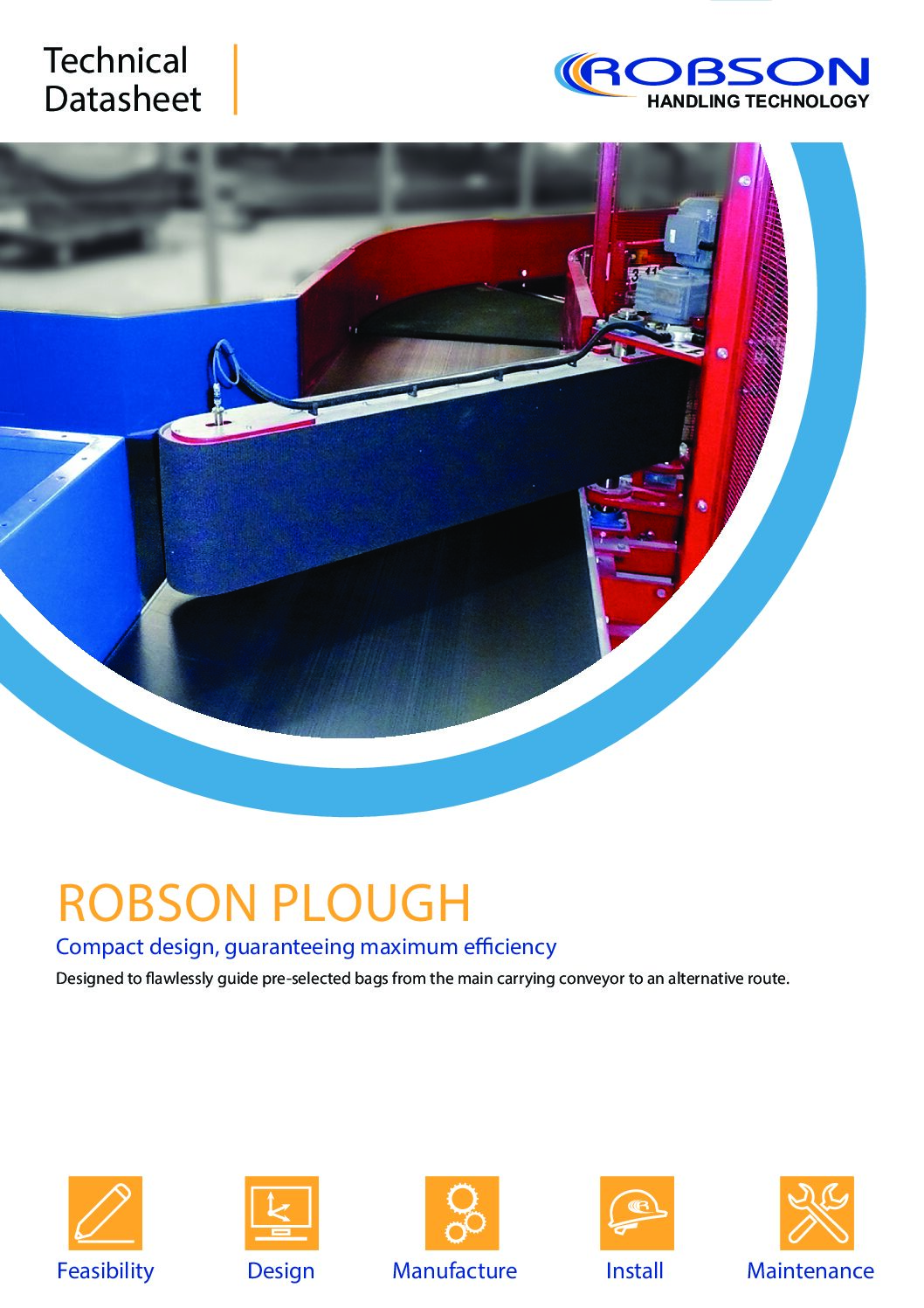

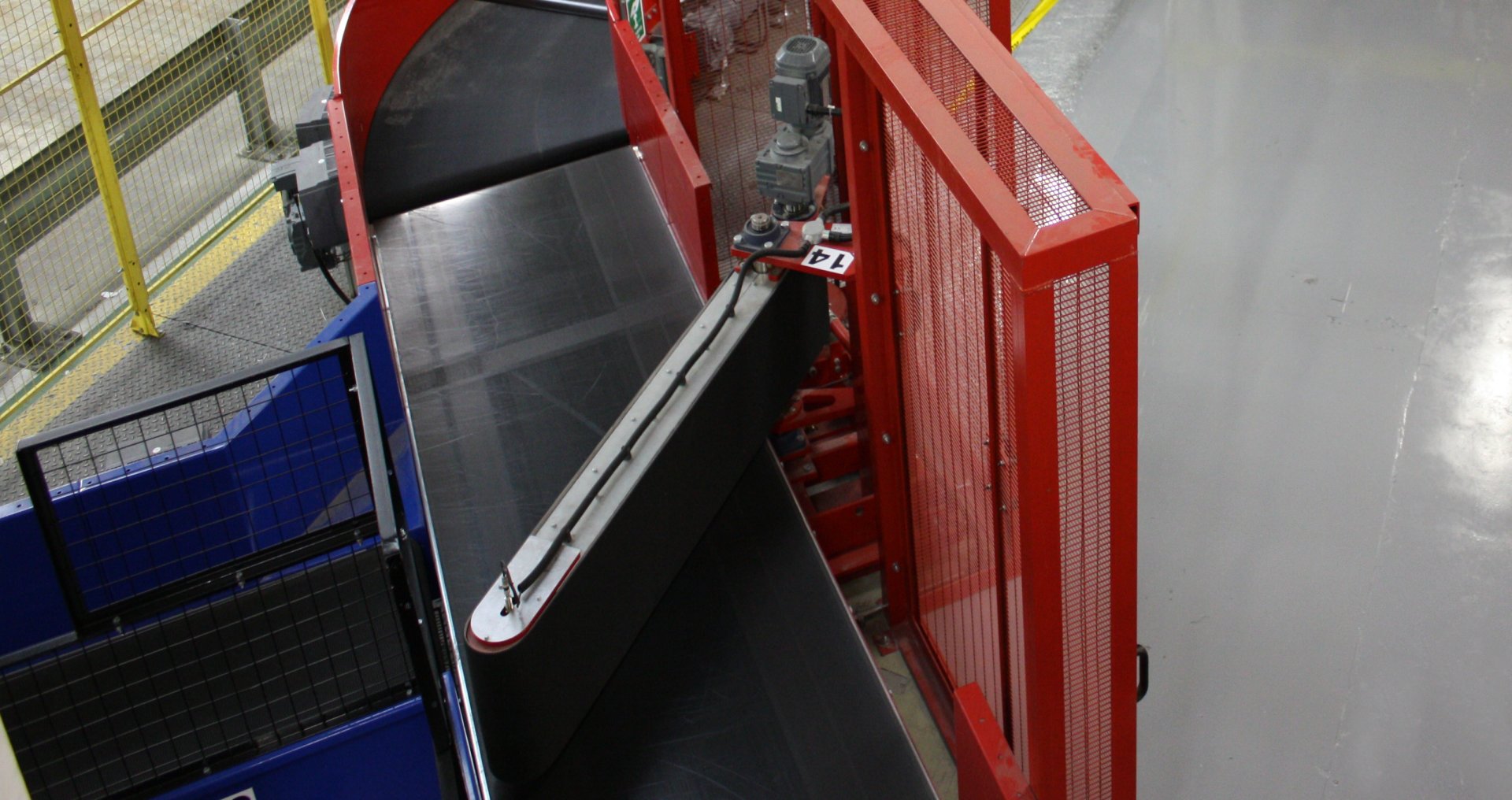

Baggage Handling Conveyors

Ultimate for speed, reliability and efficiency, with a range of conveying products to meet the needs of the most challenging of sites and surroundings.

Robson Handling Technology Baggage Handling Conveyors are constructed from pressed slider bed using mild steel plate. The conveyor casings are jig built to ensure conveyor sections are square and interchangeable.

The conveyor tension gear is guarded with painted mild steel plate guards or mesh. All nip points are fitted with painted punched mild steel plate guards. The conveyors are driven by shaft mounted geared motor units complete with torque arm fixings. Belting is flame retardant in accordance with ISO 340.

All drive frames, joint flanges and equipment fixings are fabricated from rolled mild steel flat and pressed sections. All conveyors are supplied with conveyor belts suitable for factory or site vulcanising. Punched mild steel plate to the underside of conveyors (where required) will be hinged on one side and fitted with budget locking devices or mesh under guard.

Standard Airport Conveyor Products include: Collector Conveyors, Injection Conveyors, Receiving Conveyors, Queue Conveyors, Extended Queue Conveyors and Standard Conveyors.

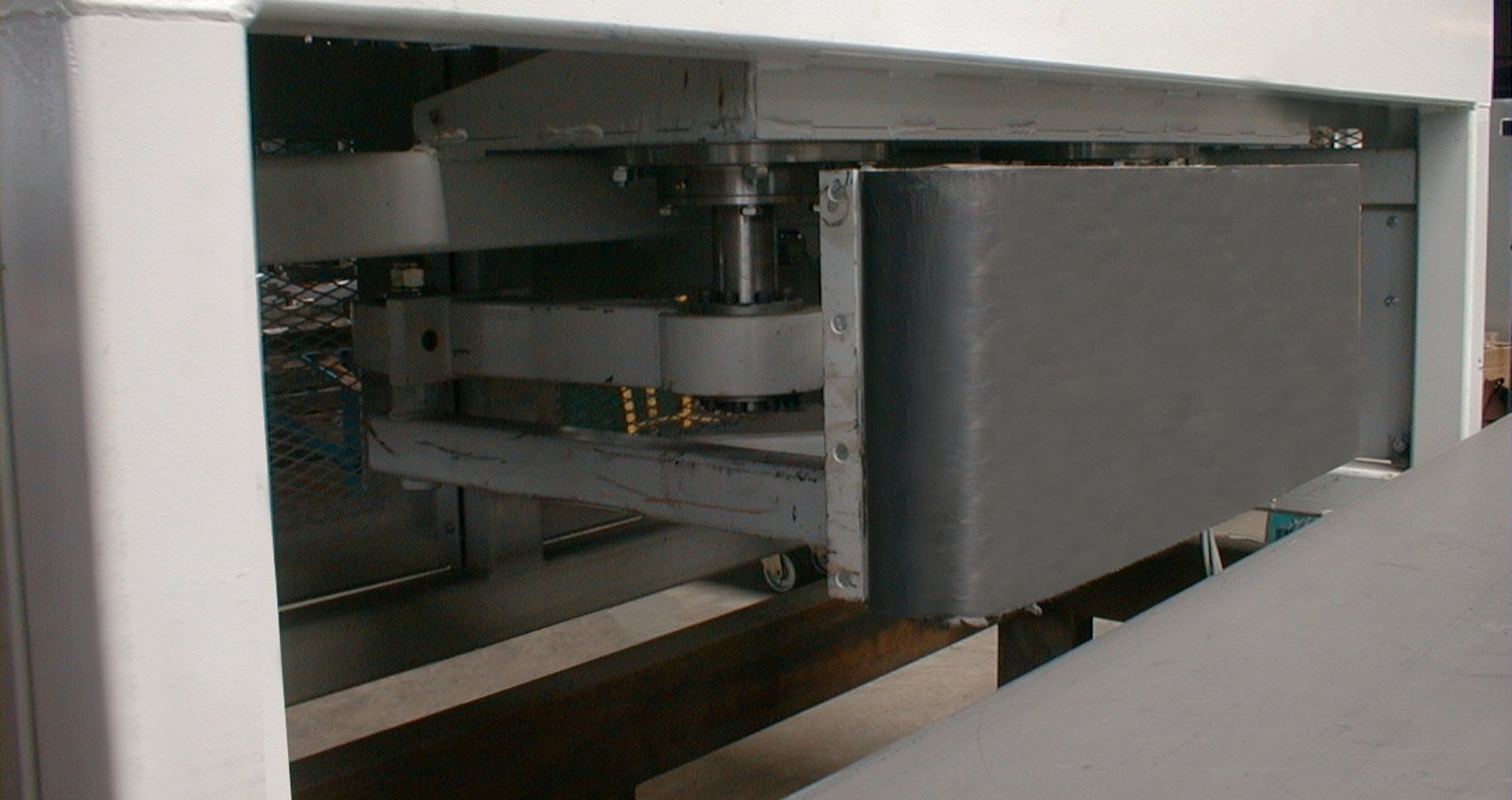

Baggage Handling Carousels

An endless surface which baggage can be displayed prior to reclaim, robustly constructed, flexible in design delivering maximum safety and user friendly features. The Carousel provides an endless surface which baggage can be displayed prior to reclaim. A combination of straight and radius sections gives the Robson carousel the flexibility to form different types of shapes such as T, U, O, L most shapes can be accommodated depending on available space.

Rigidly constructed on to a mild steel sub-frame, choices of galvanised or powder coated mild steel or x240 grit finish stainless steel casings are available.

With a nominal speed of 0.45 metres per second and having all fixings internal to the casing resulting with no protruding items plus integral Kick Plates the Robson Airport Baggage Handling Carousel ensures the safety of all uses, Baggage Handlers or Passengers.

The conveying surface comprises of overlapping flexible rubber slats, supported on the underside by steel carriers, this gives a user friendly surface that eliminates finger traps, whist having a strong support able to withstand heavy luggage.

With a choice of finishing materials, the Robson Airport Baggage Handling Carousel is ideal for Land Side or Air Side service. Available with Caterpillar Chain or Friction Drive units to suit customer requirements.