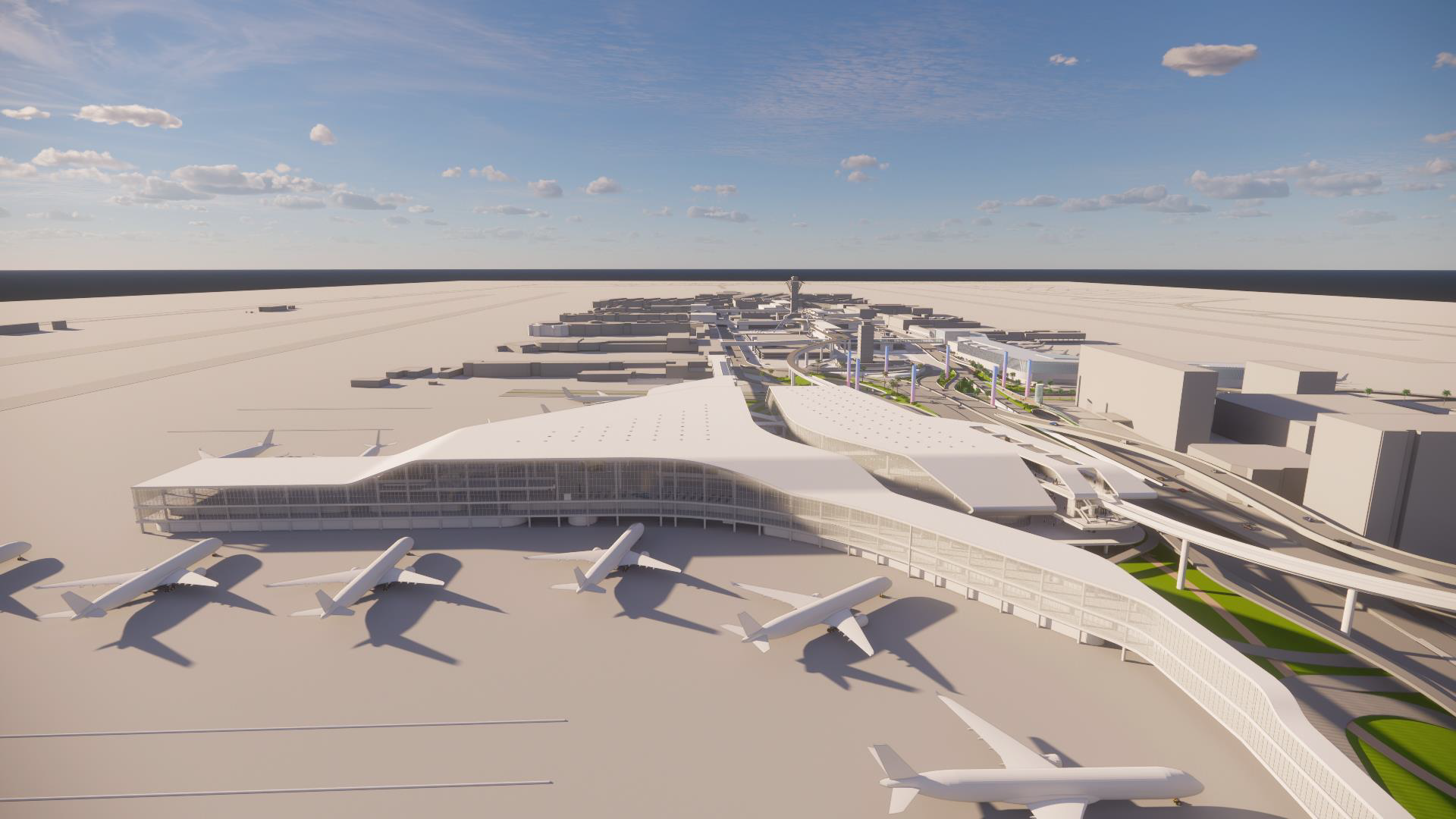

Terminal 3 at Frankfurt Airport is considered one of the largest privately financed infrastructure projects in Europe.

As part of a consortium, the Lindner Group already had a 50 percent share in the contract for Pier G of Terminal 3 in 2018 and took over the technical and commercial project management as general contractor. But this is not the end of the project for Lindner; the next project steps at Fraport have already begun.

Terminal 3: What Has Happened so Far

Back to the Lindner Group’s first contract at Frankfurt Airport’s Terminal 3: As general contractor, Lindner took on the planning, coordination, delivery and assembly work for Concourse G. With a gross floor area of around 55,000 m2, this is the first of the three new concourses and also the largest. The building is in two parts: The head building is connected to the main building and contains 22 check-in counters, including security areas, arrivals and departures with baggage claim and a retail area. The second part of the building houses the individual gates, boarding rooms and lounges. It has space for nine aircraft and can handle up to five million passengers a year. The special feature: Pier G is completely self-sufficient, can be expanded in a modular fashion and can be flexibly adapted to actual requirements. However, no aircraft are currently landing at Terminal 3, which is scheduled to open in 2026 with the completion of Piers H and J.

Design and Construction Challenges

The size of the project and the time pressure required efficient project management and coordinated cooperation between the various trades to ensure that the deadlines were met and the quality of the construction and building services was maintained. The design concept also had to be partially revised during the construction phase, which had an impact on the construction process and the schedule. In addition, sampling was carried out in parallel with the shell construction: For this purpose, Lindner converted an external hall into a 100 m² sampling area where finished rooms could be inspected and individual products could be directly evaluated and selected. Afterwards, these were used as a planning basis for the development of project-specific solutions.

Lindner Special Solution: Chilled Ceiling with Y-Slats

A number of project-specific products were developed in accordance with the architect’s wishes – for example a suspended CEILING PANEL with a cooling function. Within six months, Lindner’s Ceiling.HKT.Light division and the Research & Development department designed a functional sample, including performance measurements and installation in the sample hall. To meet the high requirements for acoustics, sound absorption and thermal insulation, the ceiling surfaces were fitted with Tektalan panels. The acoustic panels now house all the building services and the suspended Lindner chilled ceilings. As an airport building, Pier G also has to meet high structural requirements for earthquake zone 1. For this reason, the consortium opted for a ceiling rail system from which all installations can be suspended. The result is a CHILLED CEILING SYSTEM of ceiling sails covering almost 6,000 m². Foldable Y-shaped chilled ceiling segments provide the required cooling capacity and allow easy subsequent maintenance of each individual element.

Hand in Hand Towards the Goal

For the Fraport Pier G project, Lindner, as general contractor, pooled its comprehensive expertise and performance strengths for the complete outfitting: Under the direction of Lindner’s Central-East outfitting division, the Cleanroom Technology and Facility Design departments were also involved, as were Lindner Montage + Service and LEX for building materials and logistics. In addition, numerous other Lindner system products for floors, ceilings and walls from our own production were used. Together with Lindner Isoliertechnik and the ARGE partner R+S, GiB mbH was responsible for the majority of the fire protection and building physics planning as well as its supervision at Pier G.

It Goes on: VIP lounge, Check-in Hall and More

With the completion of Pier G in Terminal 3, the Lindner Group’s work on the construction site at Frankfurt Airport is entering the next round. After Lindner Isoliertechnik had already carried out extensive fire protection measures and test phases in Pier G together with GiB, further contracts for fire protection at Frankfurt Airport will now follow. In spring 2023, in parallel with the installation of a ceiling system in the check-in hall of Terminal 3, the installation of around 13,000 m2 of hollow floors including underfloor heating will begin in Building 600. Other contracts for the supply and installation of sliding partition walls in the airport’s retail areas and special ceilings for a passenger transport system in Terminals 1 and 3 will start in the next few months. Work will also continue on Concourses H and J, where special ceilings developed specifically for the project will soon be installed, as in Pier G. Meanwhile, the high-quality interior of the VIP lounge in Terminal 1, Building 222, is in its final stages and will soon be ready to welcome its first guests. The Lindner Group’s current activities at Frankfurt Airport are rounded off by a major contract for doors in the main building from Lindner’s object design division.

This article was originally published by Lindner.